Critical Risks

Creating safer, more resilient workplaces by managing critical retail and supply chain risks.

Addressing critical risks

New Zealand’s retail sector and its supply chain face significant critical risks. If unmanaged, these risks can have severe consequences for workers and businesses, impacting safety and operational resilience.

Our approach

At ShopCare, we collaborate with the sector to provide strategic and tactical solutions, driving system-level change. Our focus is on developing industry-specific guidance, case studies, and practical resources that help retailers and their supply chains manage critical risks effectively.

We work alongside industry partners to develop and share solutions that address the unique challenges within the retail sector and its supply chain. Our tools, frameworks, and guidance are tailored to meet the needs of businesses, offering practical and actionable steps to manage risk.

How Shopcare can help your business

- Our guidance and resources are designed to give you the tools to manage critical risks more effectively.

- We offer good practice frameworks, industry-specific case studies, and actionable insights, helping businesses create safer workplaces and improve overall health and safety performance.

- With our tools, you can save your business time and cost, and in turn you can focus on a more resilient operation.

Key critical risks in retail and its supply chain

Risk management is vital for businesses to understand their own exposure and give a greater focus on the risks that can result in severe injuries or fatalities. Together with key stakeholders, ShopCare has identified several common critical risks across the retail, manufacturing, wholesale, and transport sectors. These include:

Hierarchy of controls

We recommend a structured approach to manage and mitigate risks related to health and safety hazards. The hierarchy below will help you prioritise and implement control measures to minimise or eliminate hazards, starting with the most effective strategies and moving down to less effective ones.

Credit: WorkSafe

ShopCare webinar and training series

What is the difference between a hazard and a risk, and why does it matter?

Watch Michelle Cooper from Foodstuffs North Island discuss the difference between hazards and risks in our workplace safety webinar.

ShopCare critical risk guidance

ShopCare offers a variety of resources to help businesses manage these critical risks:

Line Marking guidance

Improve safety and efficiency at your site with our comprehensive guide to standardised line markings. Developed in collaboration with the retail sector and supply chain, this guide provides clear, uniform standards to improve visual communication and reduce accidents.

Click to download:

Driver Safety guidance

Developed with AA, this guidance for both employers and employees, helps organisations manage the risks associated with light passenger driver safety. It provides comprehensive insights and practical solutions for identifying and controlling critical risks in work-related vehicle travel.

Click to download:

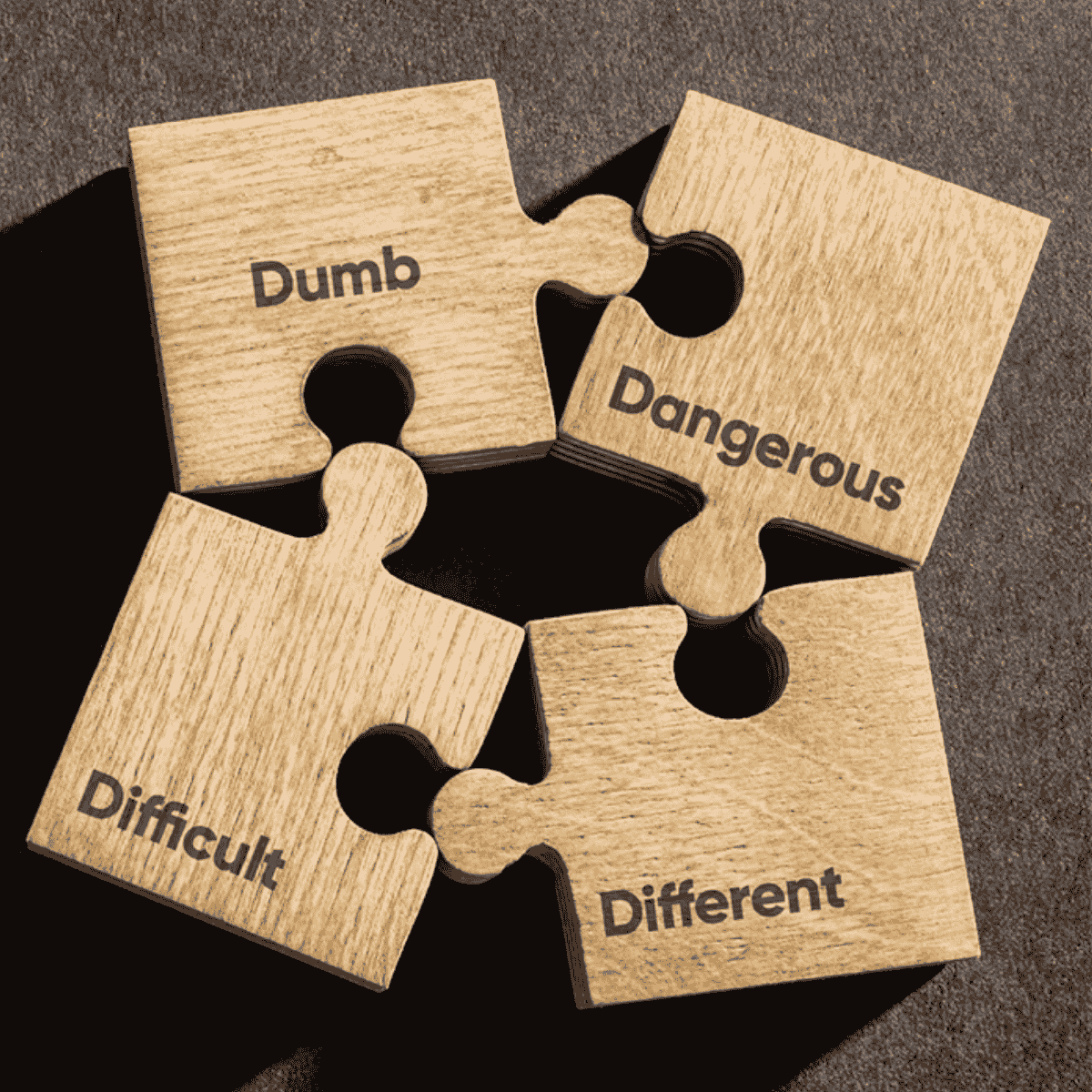

4Ds ® digital learning tools

Identifying the 4Ds (Dumb, Dangerous, Difficult, Different) helps to spot friction in everyday work before it leads to harm.

Developed in collaboration with Learning Teams Inc., ShopCare is pleased to provide online training modules and downloadable guides to support leaders, health and safety champions, and representatives. These resources will help strengthen frontline conversations and drive meaningful, practical improvement.

The 4Ds help us learn from everyday work by revealing what gets in the way of safe and reliable performance, without blame, shame or judgement of workers who face risks every day.

Click to download:

LinFox have introduced the 4Ds as a key part of their safety evolution. To help introduce the concept to their team, they created an interactive video that outlines the basic steps of the 4Ds as well as some stories and outcomes from the first sessions they ran. Watch the Linfox 4Ds video now.

ShopCare critical risk exposure report

Our 2022 report outlines the potential critical risks for the retail, manufacturing, wholesale, and transport sectors.

See the extract table below showcasing several shared risks:

Stay informed

Sign up for our emails, and you’ll be the first to know whenever we discover new resources, develop new materials, and offer new training.

8 Part Machine Safety Series

Our 8-part machine safety series with Brent Sutton, from Safety Associates, provides vital information on managing machinery risks and hazards.

Workers being harmed by machinery continues to be a growing trend. These issues are further compounded by worker shortages and the implementation of semi-automated and fully automated plant and equipment.

Build knowledge and understanding about “when and what” guarding and fencing are appropriate. And the importance of isolation and engineering controls for reducing the risks of human error.

Each 30-minute module covers topics like safety standards, hazard identification, and isolation controls.

The 30-minute machinery learning modules are:

- Trends of machinery harm, the life cycle of machinery and responsibilities of duty holders when purchasing, installing, commissioning, operations, and maintenance.

- Applying safety and design standards AS/NZS4024 in managing machinery risk.

- How machine risk is reduced using the AS/NZS4024 standards and the issues of “human error” versus “foreseeable misuse”.

- How to identify and explain the various types of physical machinery hazards.

- Understanding common health-related risks with machinery.

- Common types of machine controls and how to choose the “right guard”.

- WEPR (Worker Engagement Participation and Representation) model for managing machinery risk.

- The strengths and weaknesses of locking out plant and equipment and common safe systems of work.

Watch each of these sessions below.

Machine guarding resources

We also offer additional resources, including checklists and worksheets, to help businesses assess and manage machinery risks. Click below to view:

Valuable resources

-

BLHSF: Monitoring what matters

The Business Leaders Health and Safety Forum (BLHSF) has developed a range of resources focused on managing critical risks. Among these is Monitoring what matters, a guide designed to help CEOs and senior leaders assess and improve their approach to health and safety monitoring. While there isn’t a ‘one-size-fits-all’ set of indicators for performance, there are common drivers of success in all businesses. Effective health and safety is shaped by three key factors: risk, relationships, and resourcing.

-

Worksafe: Safe use of machinery

This WorkSafe guideline is intended for employers, engineers, designers, manufacturers, and distributors of machinery. In addition to the main guideline, WorkSafe has developed a series of fact sheets covering specific machinery types. While relevant to employers, these fact sheets are mainly directed at operators and employees to support safe machinery use.

-

WorkSafe: Trucking induction video

In this video, WorkSafe provides valuable tips on route planning, cab safety, on-site traffic management, and the safe processes for loading and unloading. These insights are particularly useful for new drivers and transport operators.

-

Worksafe: Hazardous substances

Learn how to manage hazardous substances in the workplace to ensure compliance with New Zealand’s health and safety laws. This page provides key information on legal duties, controls, and safety data requirements

-

Worksafe: How to use quantity ratio sum (QRS) to work out whether a workplace requires a ‘hazardous substance location’ (HSL) or a location compliance certificate (LCC)

Understand when a hazardous substance location or compliance certificate is required using the QRS method. This guide explains how to calculate the quantity ratio sum and interpret your results.

-

Hazardous substances toolbox

Your one-stop resource for managing hazardous substances in New Zealand. Includes access to safety data, legal obligations, best practices, and practical tools for businesses and workers.

-

Calculator – Hazardous Substances

Use this online calculator to identify legal requirements for hazardous substances stored or used in your workplace. Quickly assess controls, signage, PPE, and certification needs.